3D Printed Prototypes Canberra

If you need a prototype made in Canberra, consider 3d printing. A fast and cost-effective manufacturing process. 3D printing is a go-to option for product designers who are in need of prototypes or small batch production runs. Many businesses, schools and individuals in Canberra use 3D printers to speed up their design cycle. However, it’s not always as simple as uploading CAD files and watching the printer do its magic. These machines may appear similar, but there are many different types of 3D printers available on the market today. Each has its own specific purpose and uses different technologies to create objects from digital files. Our Canberra team can help you pick the best printer for your project, and help create a design that prints best.

What is 3D Printing?

3D printing is an additive manufacturing technology that creates objects from computer-generated designs. It works by stacking layers of materials together to create a three-dimensional object. It is one of several technologies used to create what are known as “rapid prototypes” or “rapid manufactured” products. In digital manufacturing, “rapid” refers to how quickly a design can be created, the speed with which it can be manufactured and the short amount of time it takes to complete the process. Our objects being locally printed in Canberra makes the whole process even faster. The design file is “sliced” and then transferred to a digital printer that creates the prototype one thin slice at a time.

The Advantages of 3D Printing for Prototyping

Compared to other prototyping methods, 3D printing has several advantages that make it a good option for designers. The biggest advantage of 3D printing is speed. 3D printers can turn around a model or prototype in as little as a few hours which is much faster than other methods. We can then have it delivered to you in Canberra soon after that. Another advantage of 3D printing is that prototypes can be made in small quantities since 3D printers don’t need any tooling produced for specific jobs. To create a prototype by other manufacturing methods, you would have to send the file to a manufacturer and wait for the production run to be completed. This can take weeks or months, and constant shipping delays have become the new normal. We can get your 3d printed prototype made in Canberra fast.

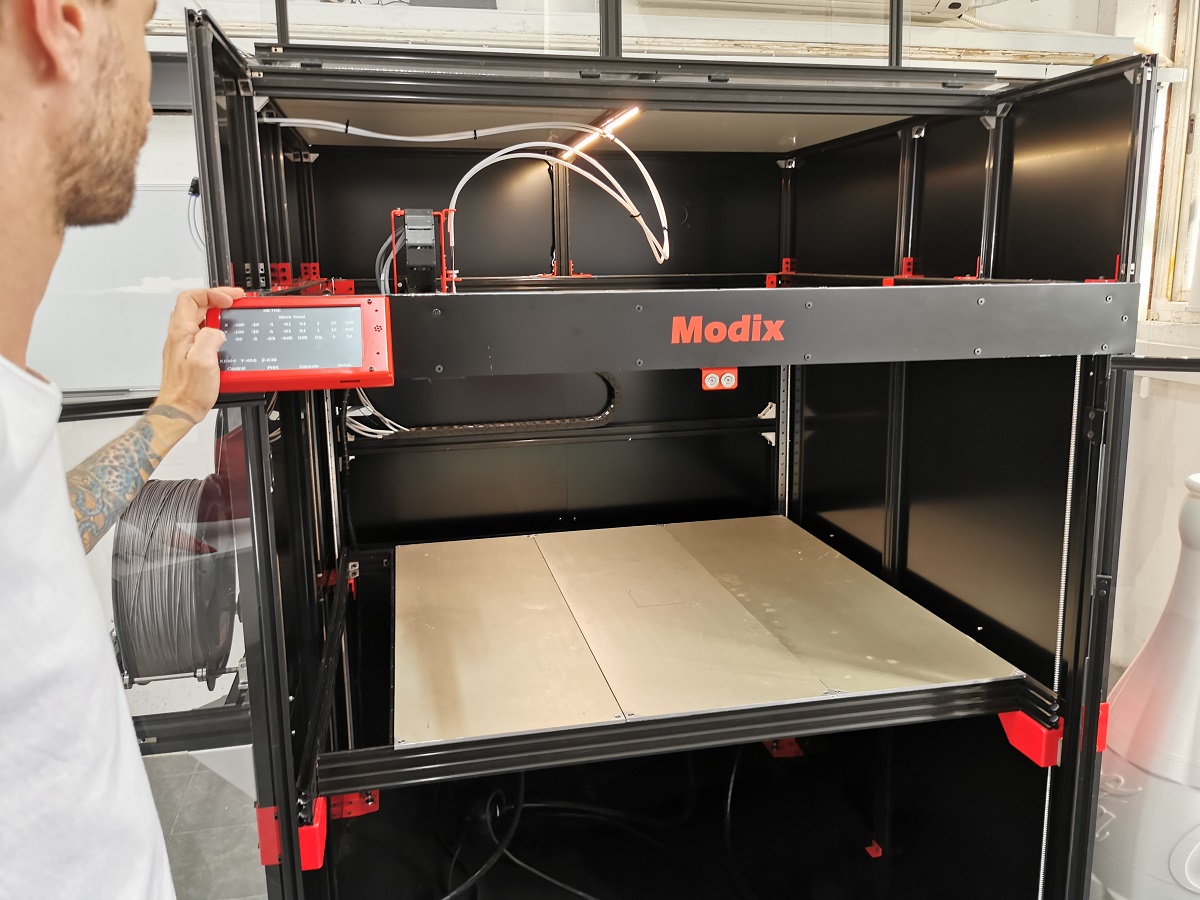

Different Types of 3D Printers

There are several different types of 3D printers on the market today. Some use a filament-based technology and others use a resin-based technology. Other more exotic techniques are also available. Filament based 3D printing uses a spool of solid plastic that the printer melts and then extrudes through a nozzle to create a layer of the object. 3D printers that use this method are called fused filament fabrication (FFF) or Fused deposition modelling (FDM) printers. – Some 3D printers use a vat of liquid resin as the build material. The printer will harden the resin by using ultraviolet light or a laser to create a layer of the object. This process is called stereolithography (SLA) or photopolymerization.

Designing for 3D Printed prototypes Canberra

One of the biggest mistakes product designers and engineers make when designing for 3D printing is not understanding the limitations of the technology. Certain shapes or geometrics on may require added supports, which adds cost, time, and wasted plastic to a build. Our team can help guide your design process to make it easy to print. This saves us all time and money.

3D Printing Processes and Technologies

Stereolithography is best for models or prototypes that require good surface finish. Such as sculptures or models destined for display, rather than functional use. FDM are best for prototypes, test objects and functional prints.

When it comes to prototyping, 3D printing is one of the fastest and most cost-effective ways to create a model or prototype. We can get your model made quickly, right here in Canberra. It’s important to understand the different types of 3D printers available and their limitations when designing. This will help prevent costly errors and ensure that your prototype will be ready for production as soon as possible. To start, contact our team to discuss the best options for you and your design.

Come and visit, get printing today!