3D printed replacement urn handle

This printing job came from our downstairs neighbour Bean Culture. They are a coffee roastery that supplies many Canberra clients with wholesale coffee. They also directly run cafés and a corporate cart business.

They came in with a hot water urn with a broken off handle. The rest of the urn still worked great, so getting a new handle 3d printed was a great option, compared to buying a whole new urn.

This part is pretty small and simple, which works great for 3D printing. It also clearly has a “base” to print on. FDM 3D printing relies on the object sticking to the bed while it prints. This part has a large, flat face making it the obvious side to place on the bed.

The tricky aspect of this design is replicating the curves on the underside of the handle. This connects to the urn valve mechanism, so has to be fairly accurate.

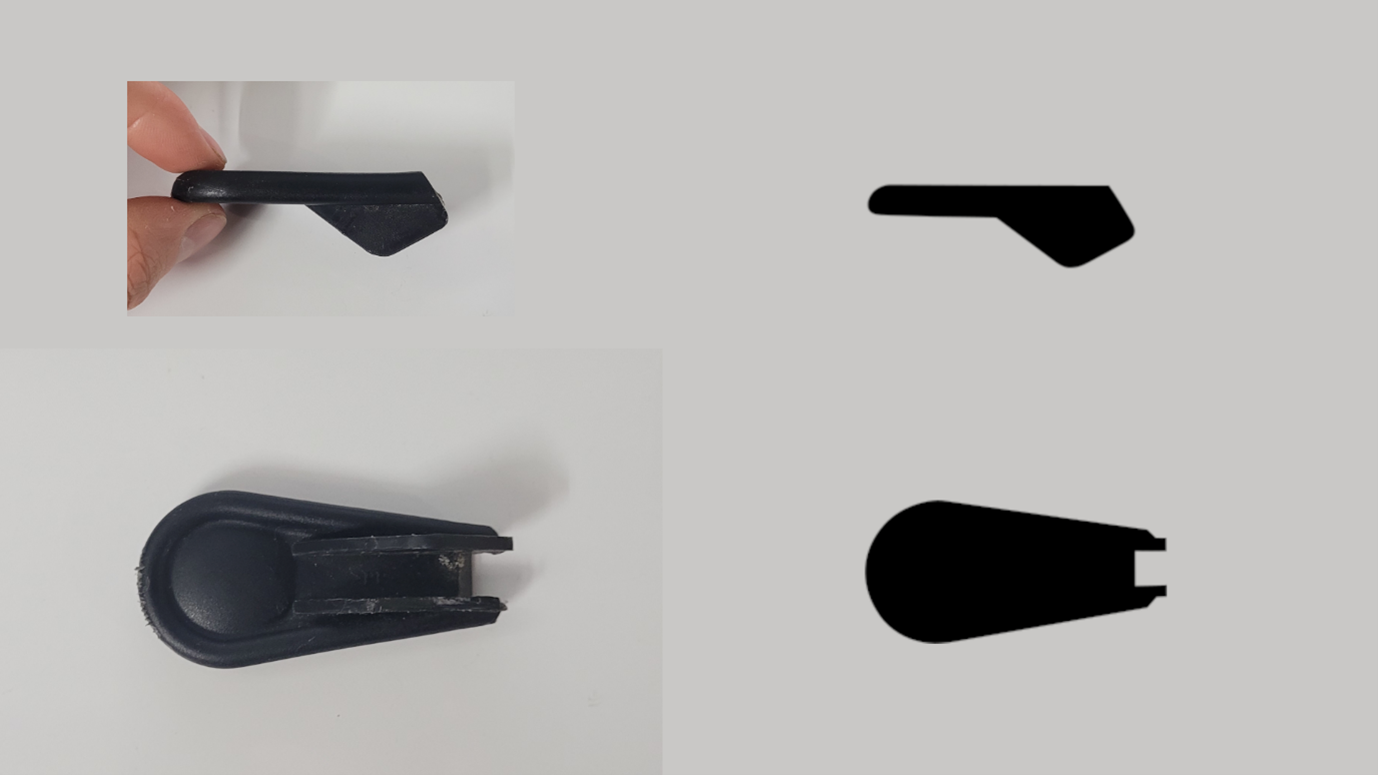

In this case the best option was to take some reference photos, turn those into vector files, which could then be fed into a CAD (Computer aided design) program to make a 3D design.

We also took one from the top, to get the general shape correct too.

These were fed into a CAD program, and after using some callipers to measure the finer details. We had a 3D model.

We printed the model out, compared to the original it looked pretty close.

We then installed it on the urn, and luckily the replacement handle works greats on the first print.

Sometimes we need to adjust tolerances slightly and re-print an object. If you do need a replacement part made, its best to bring in both the broken part, and what you need it installed on.

Need your own replacement part 3D printed? Contact us

This is our first blog post in a series. We are planning several case studies on printing jobs we have done. The aim is to help show potential customers what we do, how the process works, and how to achieve the best results. Stay tuned for more updates.